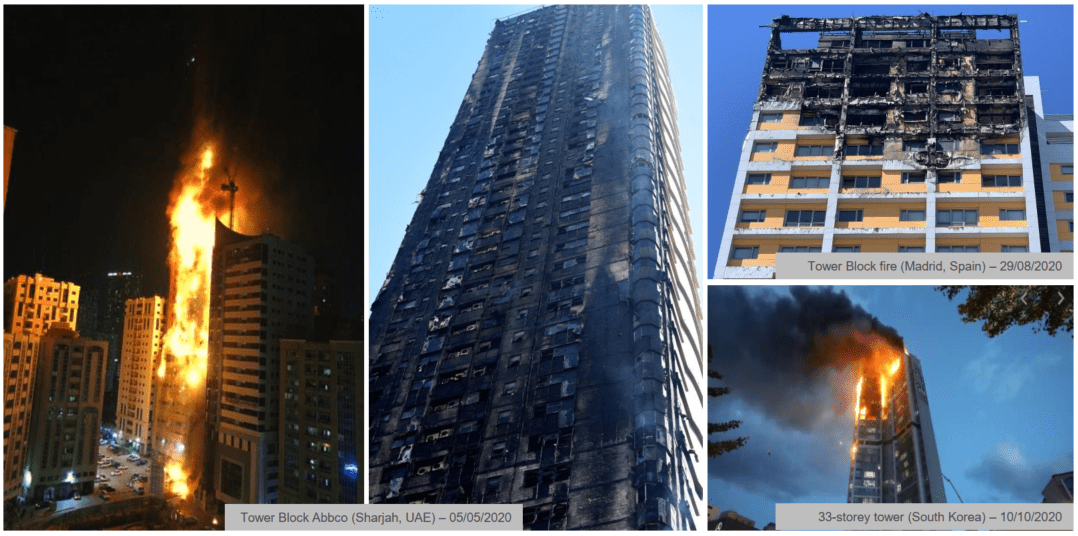

Year after Year Fire episodes keep happening in buildings all around the world.

In February this year, 2021, in the UK, it was approved a new £3.5bn funding in addition to the £1.6bn announced in 2020, to re-cladding buildings. It is estimated that 274000 flats are at risk due to dangerous/unsafe claddings.

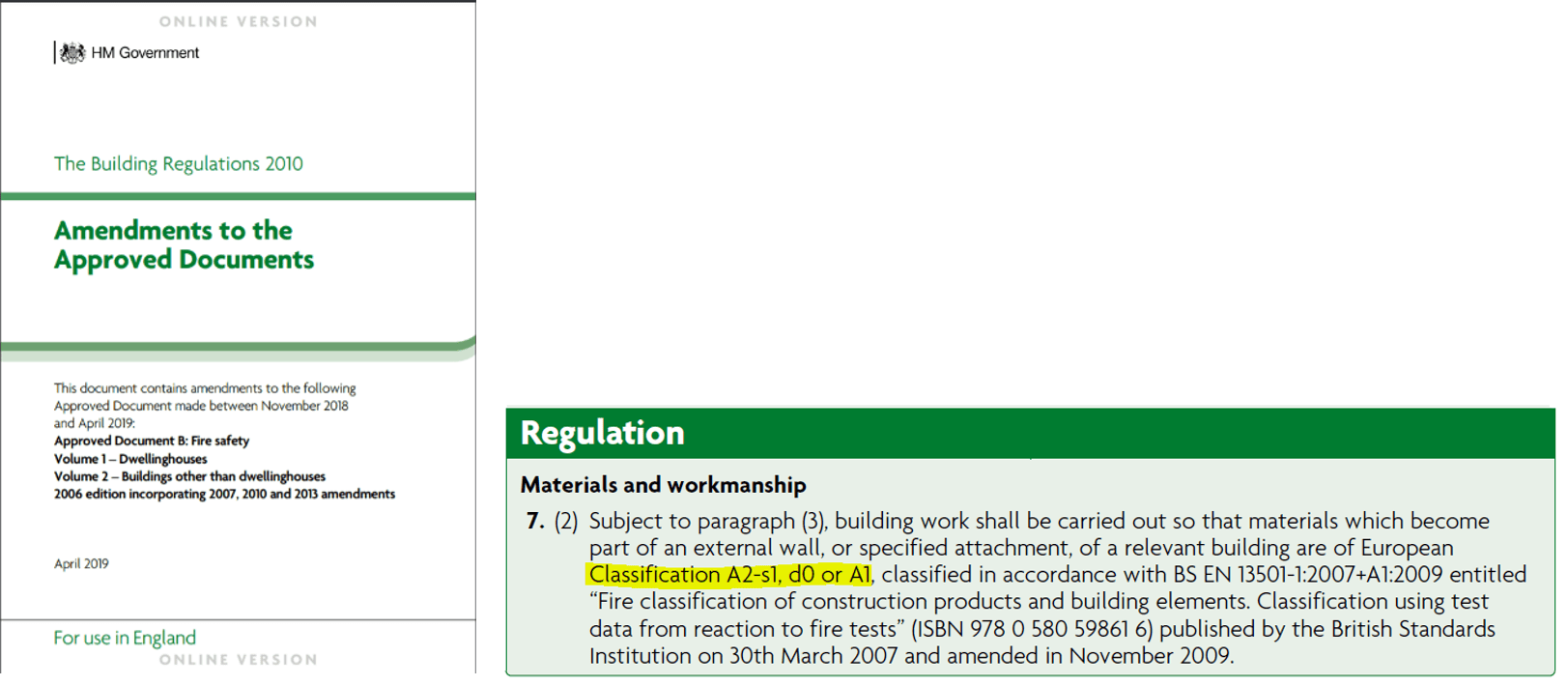

In the recent years, regulations were amended, materials were prohibited and plenty of buildings are undergoing re-cladding works.

Regulations all around the world are trying to adjust but fires episodes are still happening!

It is imperious that the construction industry and façade community develops non-combustible (or limited combustibility) solutions for the entire façade composition, protecting building property and human lives. In the end, this subject is under employee and employer liability, individually and collectively.

TECHNOLOGY IS READY – Effisus has Class A1 fire rated membranes – Non-combustible membranes

Higher fire classification in accordance with the classification standard EN 13501-1

Picture 3: Fire Rated Solutions Certifications

Effisus has product/systems available, knowledge and past experience to cooperate in project-by-project basis with architects, façade consultants, contracts, developers, building contractors, building control and building insurers. Effisus is involved in several projects ongoing at UK and Ireland, as well as others areas in Europe and Middle East.

BREATHER and AVCL SYSTEM – FIRE PERFORMANCE

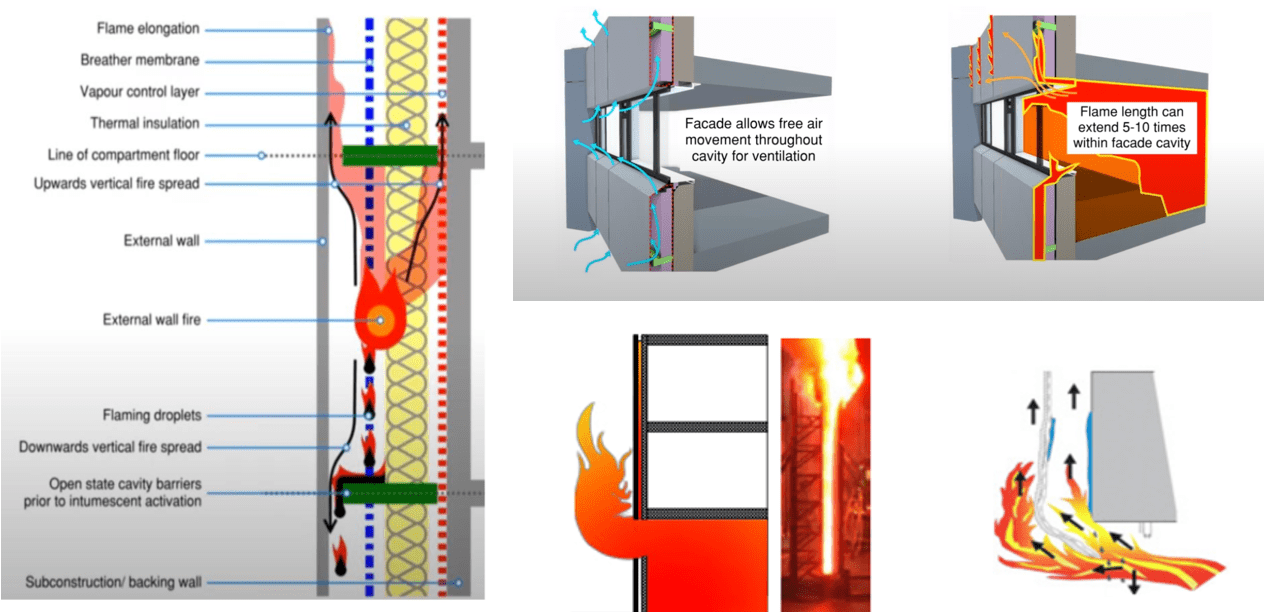

- Breather and AVCL membrane systems are facade liners (opaque areas) with severe impact on façade fire propagation – externally and internally

- Vertical & Horizontal connectivity

- It should be specified non-combustibility or limited combustibility with minimum Class A2-s1, d0 on BS EN13501-1.

- Tapes, adhesives and sealants should be tested and certified as part of membrane system always replicating the end use.

HOW FIRE PROPOGATES ON FACADE

Picture 4: Fire Propagation on Facades

CWCT/SFE fire guidance, issue 1, September 2020

“When selecting materials and products, it is vital to ensure that the proposed use is within the scope of the field of application of the test result. If the use falls outside of the scope, further assessment and/or testing may be required in order to establish he classification of the product.”

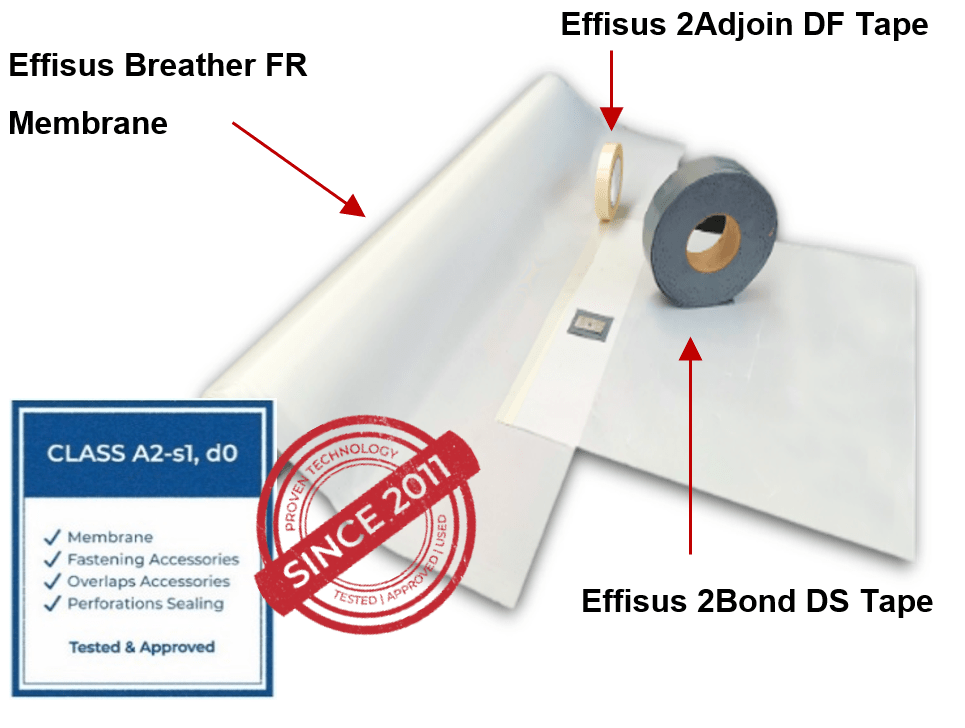

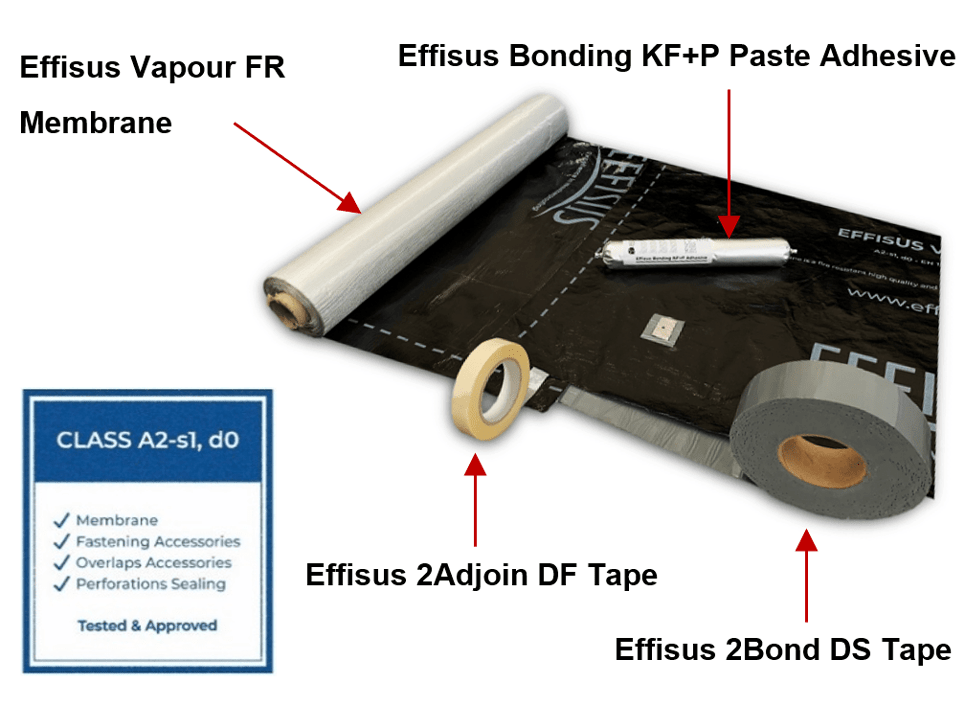

EFFISUS BREATHER FR SYSTEM and EFFISUS VAPOUR FR SYSTEM

Fire rated Class A2-s1, d0 – WEATHERPROOFING ENVELOPE SYSTEM

- Fire Reaction Class A1 (Membrane);

- Fire Reaction Class A2-s1, d0 (System);

- CE Marking;

- Full envelope system (external + internal);

- All accessories tested and compatible:

Accessories included in the fire testing

Accessories compatible with different substrates

Same accessories (external + internal) – less complexity

- 1 system provider = 1 weatherproofing design = 1 project warranty = quality control

- Easy installation procedure = less errors

Based on our experience working closely with architects, façade consultants and façade contractors, we experienced a lack of detailing on the design phase and on-site application. The membranes conceptually are well designed but when it comes to façade perforations, compatibilities with different substrates and non-common details, we notice design faults and incorrect installations.

Effisus launched recently a Fire Guidance to help designing not only the membranes but also the membrane accessories (tapes, sealants, adhesives, etc.)

For example, when we are doing the perimeter seal of AVCL (airtight vapour control system) on concrete slab, top and bottom, we need to consider two key points:

- The membrane accessory (tape, sealant, adhesive, etc) needs to be compatible with porous surface (concrete or similar): in most of the cases the standard solution (single side acrylic tapes) is incorrect. We need a membrane accessory that is compatible and has good adhesion to porous surfaces.

- There are differential movements that need to be considered when designing the correct membrane accessory – in most of the cases the standard solution (single side and double side acrylic tapes) is incorrect. We need a membrane accessory that provides elongation that accommodate movements.

Kindly share the detail drawing and price list

We have already sent the information you requested to your email. Thank you very much! For any further questions please contact us: [email protected]

Under the new UK regs we need to use fire rated cavity trays in certain types of wall build up. Is there anyway of forming cavity trays using this material?

Thank you for your comment! Your message will be answered by our Key Account Manager, via email. Thank you.

What type of certification and approval certificates could you provide to support this product in the UK market (i.e. BBA, Fire test reports, etc.)

Thank you for your comment. Your message will be answered by our Key Account Manager, via email.

For any further questions please contact us: [email protected]

Hi,

Please can you send me the BBA certificate confirming the A2-s1,d0 compliance?

kind regards,

kane

Thank you for your comment. Your message will be answered by our Key Account Manager, via email.

For any further questions please contact us: [email protected]

Could you kindly please send me a copy of the price lists and the relevant certification for your Effisus FR A2 rated membrane?

Thank you for your comment. Your message will be answered by our Key Account Manager, via email.

For any further questions please contact us: [email protected]

Hello

Can you provide all certifications and technical data sheets for your product. Also can you confirm its availability on the UK market as well as contact details for your UK representative/agent. Thank you ever so much.

Thank you for your comment. Your message will be answered by our Key Account Manager, via email.

For any further questions please contact us: [email protected]

Hello

Can you send me information on technical data sheets, certification, details of product availability in the UK, contact details of UK representative/agent.

Thank you.

Thank you for your comment. Your message will be answered by our Key Account Manager, via email.

For any further questions please contact us: [email protected]

Can you provide the technical data sheets for Effisus FR. Please confirm if this product is tested and accredited for use as a cavity tray. Also can you confirm its availability on the UK market and contact details for your rep .

Can you provide the technical data sheets for Effisus FR. Please confirm if this product is tested and accredited for use as a cavity tray.

Thank you for your comment! Your message will be answered by our Technical Office Manager, Miguel Silva, via email. Thank you.

Can you provide any technical data sheets for Effisus FR.

Is this product suitable and accredited for use as a cavity tray? Are any BBA certificates available?

Dear Martin Fox,

Thanks for your question. We will send the datasheet directly to your email address.

We are working closely with Labs and our R&D Dep to evaluate the possibility of application of Effisus FR as a cavity tray.

We are also proceeding with BBA for our full façade envelope system – final certification will be available later this year.

Please forward details of the planned certification. We consistently come across this issue and are keen to mitigate the project costs of adopting a stainless steel system.

Keen to understand more about your product, applications and plans for testing/certification of same as a cavity tray.

We are also often asked for classified materials to use as DPC and perpend weepholes. Any potential for adopting your product, and an understanding of costs & spec would be appreciateed

Many thanks for your enquiry. We have an R&D open project in regard to cavity tray. Our solution will not be based on stainless steel system as we know it is not cost-effective, we are currently studying the product possibilities in accordance with the project technical requirements, test standards and fire performance. For a fully tested solution, it will still take some time but we will communicate at that time.

Hi, please can you send me the data and application usage for this product as a cavity tray. Pricing and availability too if possible

Hi Ryan, regarding cavity tray, we are in the concept design phase working closely with the Labs and our R&D Dep. We are currently studying the product possibilities in accordance with the project technical requirements, test standards and fire performance. Consequently, we will proceed with the testing and product certification BBA, but we still need some time for a fully tested solution. Let us know if I can be of any further assistance.

Hi , do you produce any cavity tray to non combustible?

Many thanks

In regards to cavity tray, we are in the concept design phase working closely with the Labs and our R&D Dep. We are currently studying the product possibilities in accordance with the project technical requirements, test standards and fire performance.

We are applying in several projects our FR A2-s1,d0 fire-rated weatherproofing systems. (Breather and AVCL membrane). For more details please contact our UK Account Manager at: [email protected]