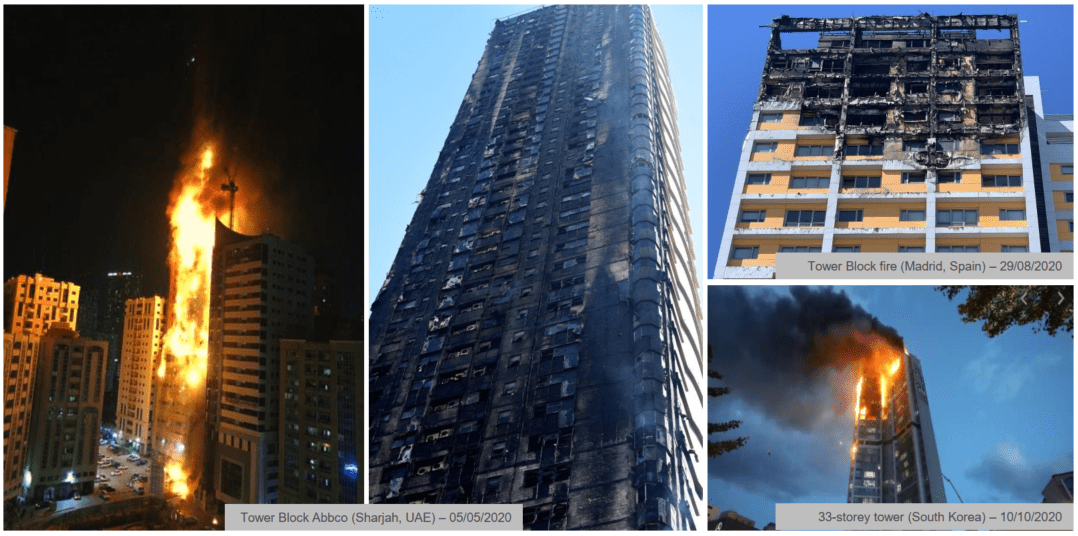

Year after Year Fire episodes keep happening in buildings all around the world.

In February this year, 2021, in the UK, it was approved a new £3.5bn funding in addition to the £1.6bn announced in 2020, to re-cladding buildings. It is estimated that 274000 flats are at risk due to dangerous/unsafe claddings.

In the recent years, regulations were amended, materials were prohibited and plenty of buildings are undergoing re-cladding works.

Regulations all around the world are trying to adjust but fires episodes are still happening!

It is imperious that the construction industry and façade community develops non-combustible (or limited combustibility) solutions for the entire façade composition, protecting building property and human lives. In the end, this subject is under employee and employer liability, individually and collectively.

TECHNOLOGY IS READY – Effisus has Class A1 fire rated membranes – Non-combustible membranes

Higher fire classification in accordance with the classification standard EN 13501-1

Picture 3: Fire Rated Solutions Certifications

Effisus has product/systems available, knowledge and past experience to cooperate in project-by-project basis with architects, façade consultants, contracts, developers, building contractors, building control and building insurers. Effisus is involved in several projects ongoing at UK and Ireland, as well as others areas in Europe and Middle East.

BREATHER and AVCL SYSTEM – FIRE PERFORMANCE

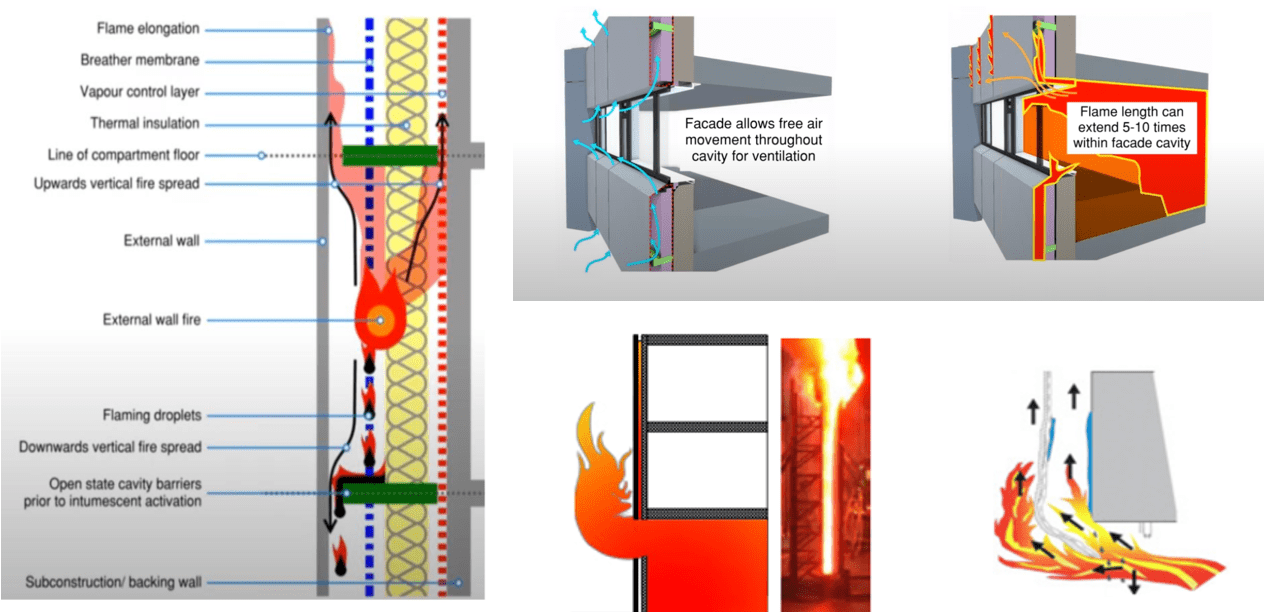

- Breather and AVCL membrane systems are facade liners (opaque areas) with severe impact on façade fire propagation – externally and internally

- Vertical & Horizontal connectivity

- It should be specified non-combustibility or limited combustibility with minimum Class A2-s1, d0 on BS EN13501-1.

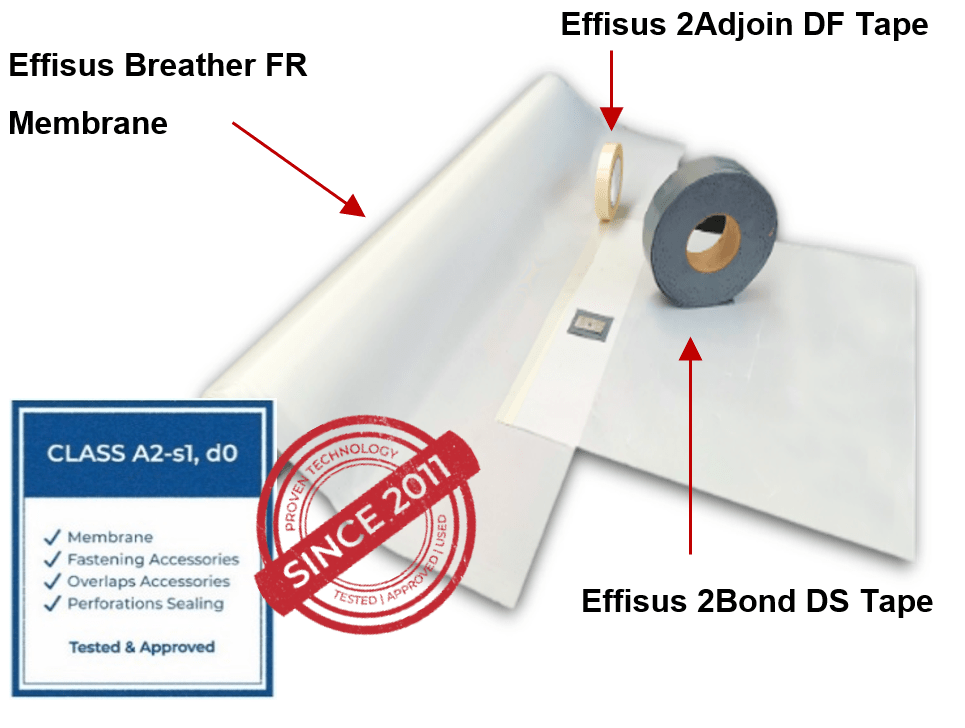

- Tapes, adhesives and sealants should be tested and certified as part of membrane system always replicating the end use.

HOW FIRE PROPOGATES ON FACADE

Picture 4: Fire Propagation on Facades

CWCT/SFE fire guidance, issue 1, September 2020

“When selecting materials and products, it is vital to ensure that the proposed use is within the scope of the field of application of the test result. If the use falls outside of the scope, further assessment and/or testing may be required in order to establish he classification of the product.”

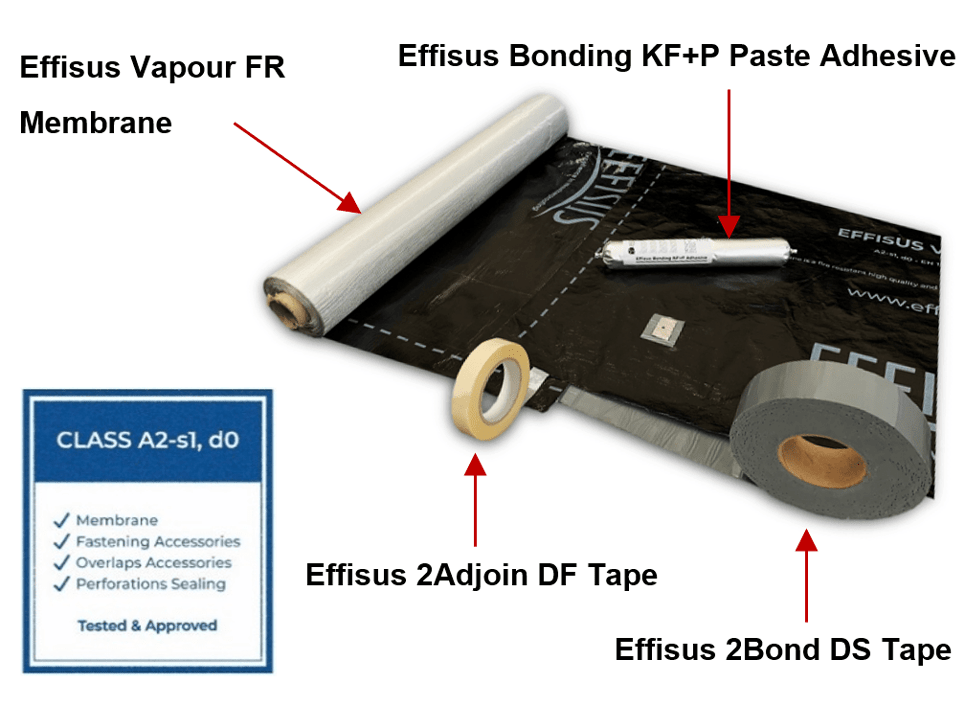

EFFISUS BREATHER FR SYSTEM and EFFISUS VAPOUR FR SYSTEM

Fire rated Class A2-s1, d0 – WEATHERPROOFING ENVELOPE SYSTEM

- Fire Reaction Class A1 (Membrane);

- Fire Reaction Class A2-s1, d0 (System);

- CE Marking;

- Full envelope system (external + internal);

- All accessories tested and compatible:

Accessories included in the fire testing

Accessories compatible with different substrates

Same accessories (external + internal) – less complexity

- 1 system provider = 1 weatherproofing design = 1 project warranty = quality control

- Easy installation procedure = less errors

Based on our experience working closely with architects, façade consultants and façade contractors, we experienced a lack of detailing on the design phase and on-site application. The membranes conceptually are well designed but when it comes to façade perforations, compatibilities with different substrates and non-common details, we notice design faults and incorrect installations.

Effisus launched recently a Fire Guidance to help designing not only the membranes but also the membrane accessories (tapes, sealants, adhesives, etc.)

For example, when we are doing the perimeter seal of AVCL (airtight vapour control system) on concrete slab, top and bottom, we need to consider two key points:

- The membrane accessory (tape, sealant, adhesive, etc) needs to be compatible with porous surface (concrete or similar): in most of the cases the standard solution (single side acrylic tapes) is incorrect. We need a membrane accessory that is compatible and has good adhesion to porous surfaces.

- There are differential movements that need to be considered when designing the correct membrane accessory – in most of the cases the standard solution (single side and double side acrylic tapes) is incorrect. We need a membrane accessory that provides elongation that accommodate movements.