From our experience of working closely with constructors, architects and facade consultants/contractors in the facade weatherproofing industry, one problem that we at Effisus frequently face is a lack of detail in the design phase of membranes which can then have a knock-on effect in the construction phase.

Weatherproofing membranes are usually conceptually very well designed. However, instructions for their on-site installation are often neither very well defined nor are they clear as to which accessories should be used (adhesives, sealants, tapes, etc.). In most cases, there is a lack of compatibility between the substrates of the façade and the accessories used to fix the weatherproofing membranes. This can lead to several problems, such as water leakage, which can impact on the life expectancy of the building and on the quality of life of those who live in it.

It is, therefore, crucial to ensure compatibility between the different materials that are in contact at the project level. Analysis of such compatibility should be done at the design stage of the project so as to avoid problems later on in the on-site application phase.

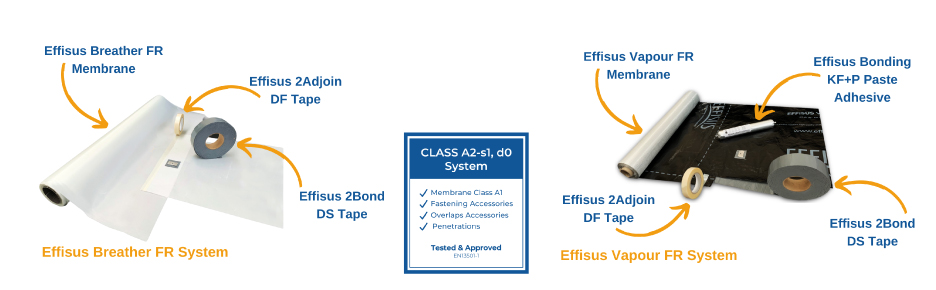

With this in mind Effisus fire-rated systems include not only the membranes, but also all the required accessories, such as tapes and adhesives.

The Effisus Breather FR System, a breathable membrane, and the Effisus Vapour FR System, an air and vapour control layer (AVCL), come with a full set of accessories which allow solutions to each different situation and substrate faced by workers on site. Each accessory has different characteristics and can be used for different purposes in the installation of the membranes. Which accessory to be used with which membrane should always be considered on a case by case basis according to the project requirements.

Fixing to the substrate

When fixing the membranes to the substrate, the accessory (tape, sealant, adhesive, etc.) needs to be compatible with the substrate and the membrane itself.

Dealing with a porous surface (concrete, masonry, blockwork, etc.) by using a standard solution such as a single-sided acrylic tape, is incorrect; a membrane accessory that is compatible and has good adhesion to porous surfaces must be chosen. These cases require the use of a robust tape > 1,50mm thick, such as Effisus 2Bond DS Tape, or an adhesive/sealant solution, such as Effisus Bonding KF+P paste adhesive.

On smooth surfaces, such as SFS studs, aluminium/steel elements and sheathing board, the membrane can be fixed to the substrate using a double-sided acrylic adhesive tape, such as Effisus 2Adjoin DF Tape. This tape is solvent free, provides moisture resistant sealing and is compatible with a wide range of different substrate materials.

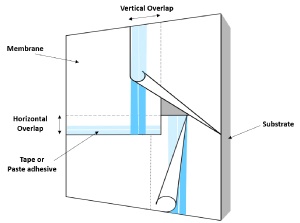

Membrane overlap

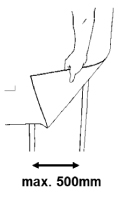

Membranes should always be overlapped correctly so that the membrane can perform its function properly. Recommendations for the overlap widths and component/accessory to be used are related to the base material and the weight of the membrane.

Effisus’ recommendations for the FR Systems mentioned above is to apply 2 bands of Effisus 2Adjoin DF Tape for both the Effisus Breather FR membrane and Effisus Vapour FR membrane. Wherever necessary, the appropriate accessory can be adjusted according to the specifications of the job; for instance, Effisus Bonding KF+P paste adhesive can be used alternatively with Effisus Vapour FR membrane.

Vertical foils should overlap 150 mm while horizontal foils should overlap 100 mm; always bearing in mind optimal water flow.

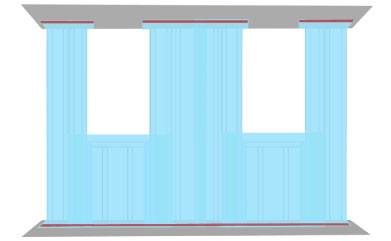

Perimeter sealing

The perimeter sealing of the membrane, often onto a porous substrate such as concrete, should be considered with equal care and attention. This procedure calls for the use of a robust tape with a thickness of > 1,50mm, such as Effisus 2Bond DS Tape, or an adhesive/sealant solution, such as Effisus Bonding KF+P paste adhesive.

Correct perimeter sealing of the membrane will ensure that water leakage will not occur around the entire membrane, at its end connections, where the weatherproofing system is most susceptible to failure and a correct sealing becomes even more crucial.

All accessories should be considered and designed according to the specific requirements of each project and should always be included in any testing, in order to guarantee maximum efficiency of the solution in its final end use.

This analysis highlights the importance of compatibility between the most common substrates used in construction and those accessories used to fix and properly install weatherproofing membranes onto the façade of a building.