Metal roofs

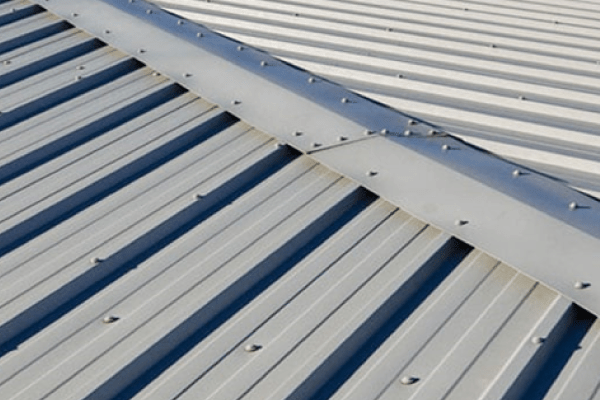

A metal roof is a roofing system made from metal pieces or tiles, lightweight, with high resistance, weatherproof and durable. Metal roofs are an excellent solution for buildings with complicated shapes. They are light but capable of supporting enormous weights and their repairability is very simple without affecting the rest of the construction.

The use of metal roofs in commercial and industrial buildings has always been significant, but thanks to their many characteristics and properties and the aim to achieve a more modern and contemporary appearance, they are also being used in public buildings and private residential buildings.

Main advantages and disadvantages

Advantages:

– Useful for closing large areas without intermediate supports;

– Good weight-resistance ratio;

– High ductility;

– Homogeneous material that reduces human errors when applying it;

– Resists structural movements of the construction;

– Fast assembly, as the elements are prefabricated;

– Increased wind resistance.

Disadvantages:

– The high resistance of the material causes stylisation problems;

– They need high protection against corrosion and fire;

– Higher price than reinforced concrete;

– Great care of joints due to the movements of the structure;

In this article, we will analyse the problems that appear in the flashing details of these metal roofs, which are the main causes of leaks due to their lack of insulation:

A – Metal roofing flashing and the challenges involved

B – Standard solutions on the market

C – The Effisus Solution

D – Application examples

A – Metal roofing flashing and the challenges involved

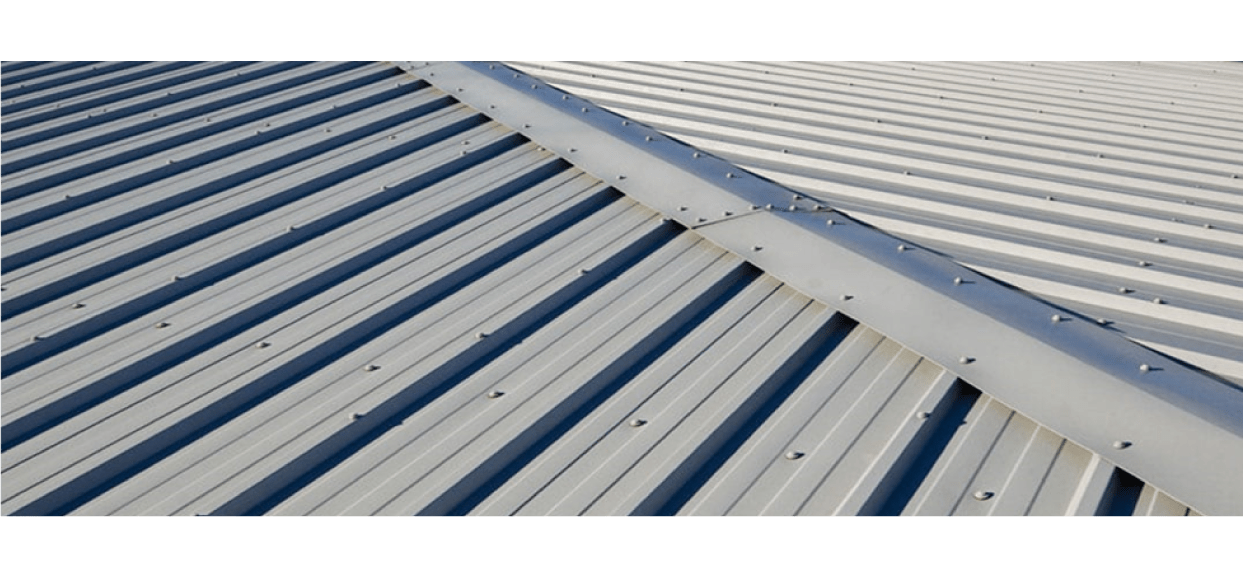

1- PANEL JOINT ON THE TOP OF THE ROOF

The connection of metal panels at the ridge of a roof is always a challenge when it comes to preventing leaks and protecting a building. This part of the construction, where an inverted V-shaped space with different inclinations is usually created, is not always properly closed and causes an important thermal bridge for air or water access.

The interior lining of the roof is often made with a corrugated profiled panel, which in some cases, does not present a drainage finish at the junction with the sandwich panel of the roof and causes a source of entry of water.

www.picuki.com/media/2230729089563058602

http://lucernarios.es/policarbonato-compacto-grecado/

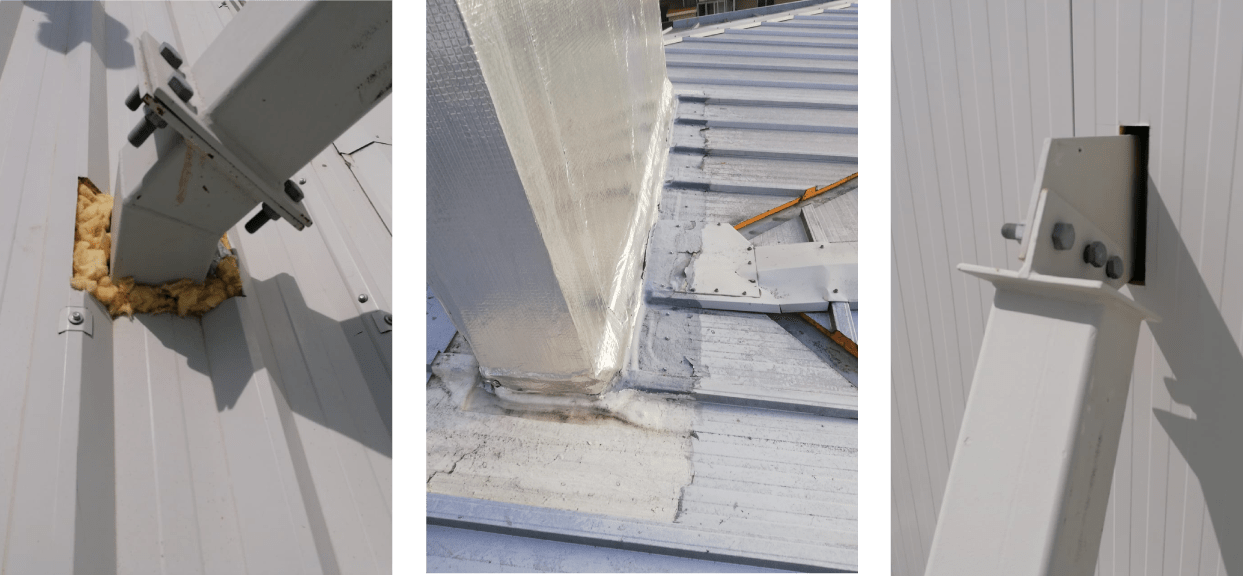

2- PERFORATIONS

The crossings along a roof are one of the most critical areas or “black spots”. Columns, chimneys, anchorages (antennas, signs, etc.), crossovers, expansion joints, etc. are examples of quotidian situations that can cause many insulation problems or leaks.

Perforations that are not properly weatherproofed drain water inside, deteriorating the roofs, interior coatings and the structure of buildings.

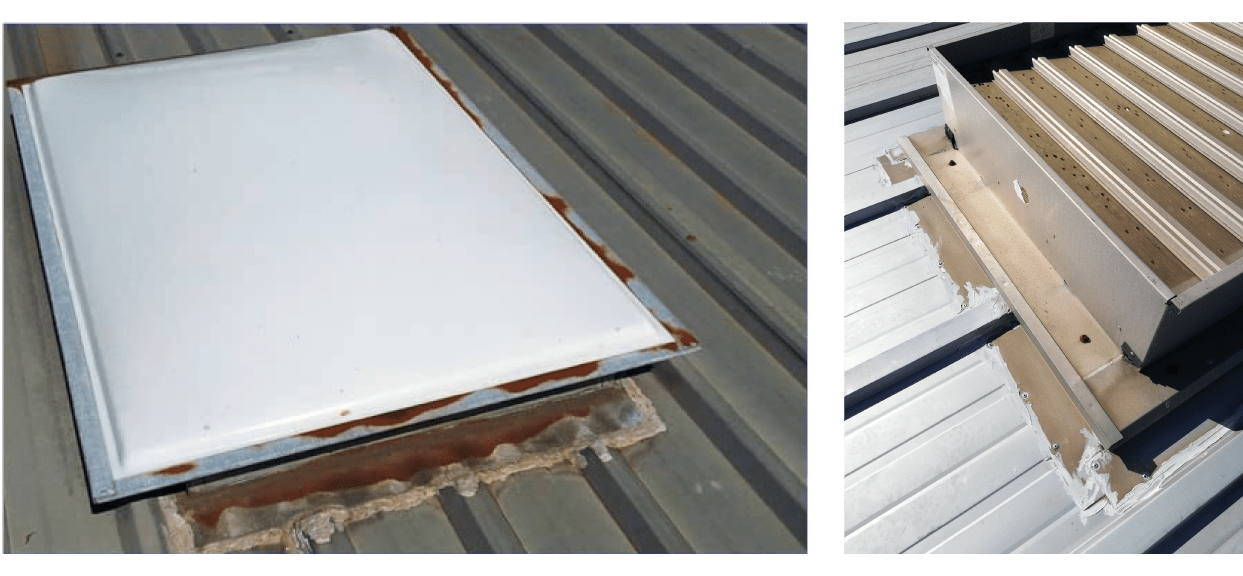

3- SKYLIGHTS

Skylights, sources of illumination in so many buildings, have also become one of the main problems of leaking and humidity in a building. What really causes the filtrations are the joints of the skylight.

In some cases, the leaks are carried out by breaks in their unions or because of the structural movements of the buildings. Poor or badly finishes, incorrect installations or large condensations are some of the causes of these leaks. Over time, finding these problems is difficult and costly.

4- PERIMETER FINISHES WITH PARAPETS OR WALLS

Perimeter finishes on flat roofs are often tricky areas for perfect sealing and waterproofing. Wherever there is a union or connection between two surfaces with different slopes, both open and closed angles present a problem.

In time, because of weather conditions and due to the fact that these spots have a big exposure, high structural movements and are areas susceptible to water stagnation, they manage to cause moisture and leaks. It is very important to achieve from the very first moment perfect insulation to avoid future damage.

https://commercialroofusa.com/metal-roof-flashing/

https://arquitecturasimple.com/humedad-por-filtraciones/

B – Standard solutions on the market

1- USE OF SILICONES

The most common solution when sealing joints, connections or finishes, is the use of some type of silicone. It is a quick and economical solution as silicone has a very simple application and does not require specialized labour. On the other side, its durability is limited – it is a good option when a long-term solution is not required. After a few months, due to the movements of the construction in question, the silicone seals end up fracturing and leaving the joints unprotected.

http://www.gtm.sodimac.cl/sodimac-cl/content/a70038

https://commercialroofusa.com/metal-vent-caulking/

2- LIQUID WATERPROOFING

Liquid waterproofing is seen as an easy solution to apply especially when we are considering details with complex shapes, sharp angels and limited space, that are difficult to seal with typical waterproofing membranes. The main difficulty related to such solutions is that the quality of the final solution will be totally dependant on the quality of workmanship – full control of the layers applied and its thickness is required in order to assure proper durability. It is very difficult to maintain the same thickness over the entire application surface, which makes it an incomplete solution and can cause problems over time.

Liquid solutions often struggle to absorb movements on metal roof connections which will commonly lead to typical cracks as seen on the pictures below.

https://howlongdoesrooflast.com/how-to-overcome-leaking-metal-roof/

3- ASPHALT MEMBRANES AND WELDING

The use of asphalt membranes is another of the most commonly used solutions. This solution has long been established in the market, and can have proper durability, especially on flat roof applications. On the other side, it is important to note that its installation always requires specialised labour and tools since it is applied with a torch – this may be a higher limitation when we consider schedules and costs. Its application for sealing intricate flashing details is also difficult as it is a material with limited flexibility, and can get loose from the surface after some time of dealing with high temperatures and continuous cycles of expansion and contraction.

https://www.pinterest.ca/pin/377246906266640468/

http://www.roofingmagazine.com/self-flashing-skylights-commercial-warehouses-beginning-leak/

C – The Effisus Solution

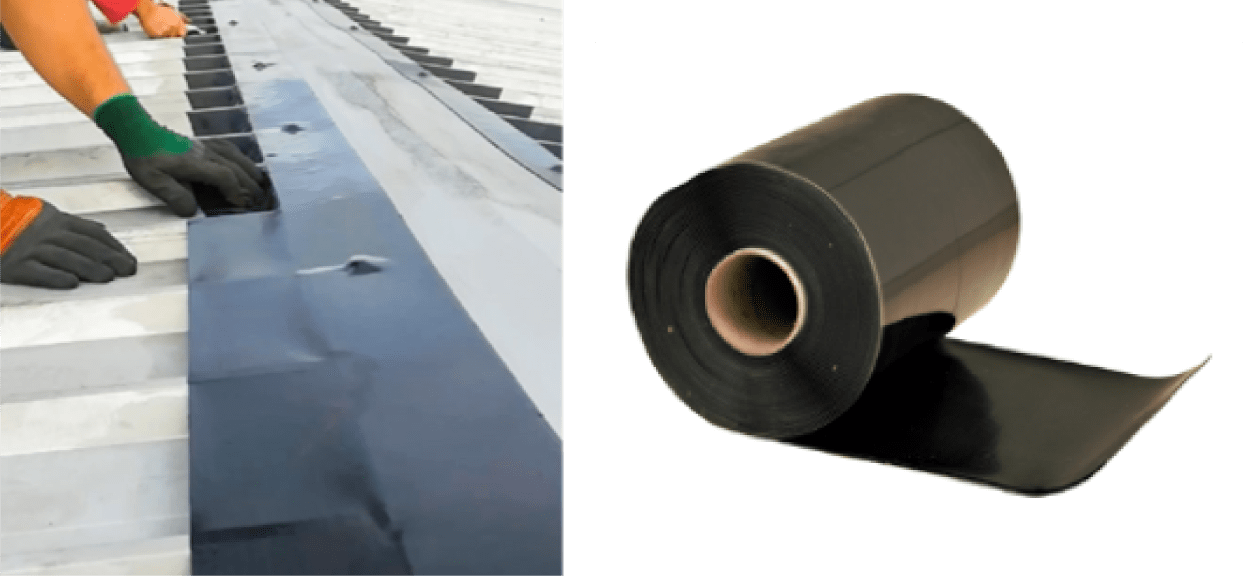

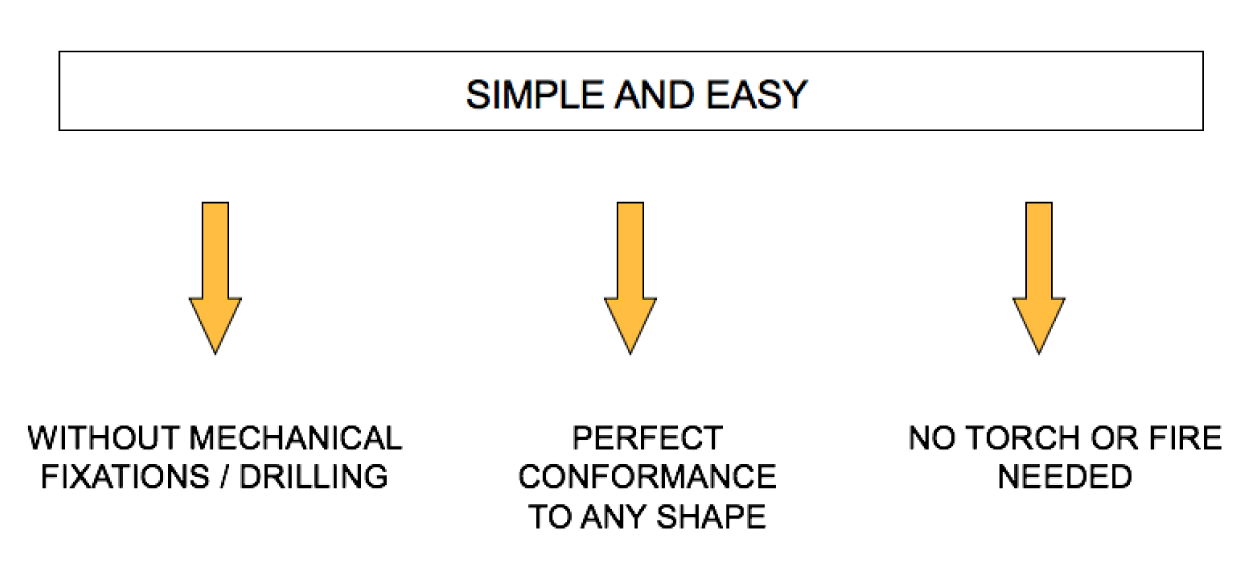

Throughout this article, we have talked about different problems presented in theconnections of a metal. There are many solutions available in the market to solve them but here we will present a single product to be used in all the mentioned applications, thanks to its versatility and polyvalence. We are talking about the Effisus Bond FT Tape.

It is an ideal solution for permanently sealing flashing details on metal roofs of any type, saving time and labour – with a superior performance that will last as long as the roof. Its unique elongation capacity and flexibility guarantees that it can be formed to fit irregular shapes and surfaces, with no need for mechanical fastening, torch or extra adhesives.

The composition of the Effisus Bond FT Tape consists of an uncured EPDM membrane that has been laminated to a pressure-sensitive EPDM tape, incorporating a tested “peel & stick” technology. Once cured, the tape is extremely resistant to moisture, UV’s, temperature variations and structural movements.

Solution benefits:

– Universal – Forms itself to fit any irregular shape or surface.

– Resistant – High elongation capacity, handles expansion and structural movements.

– Durable – Resistant to high temperature, UV’s and moisture.

– Flexible – Complies with different project requirements.

– Easy to install – Easy to handle materials and common use accessories.

– Compatibility – Compatible with many of the substrates used in construction.

D – Application examples

It suits all kind of situations like the following ones:

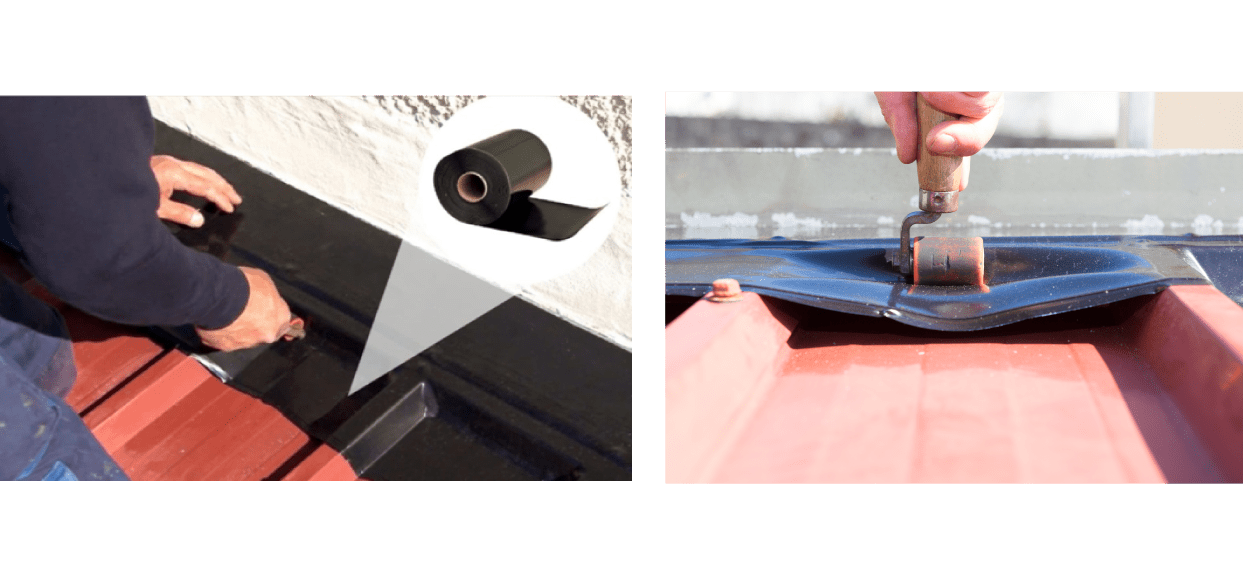

1- Panel joint on the top of the roof

Scope of work: sealing of roof ridge

Solution used: Effisus Bond FT

Installation description:

– Step 1: applying the Effisus Coat SP Primer and allow it to completely dry.

– Step 2: adhering the Effisus Bond FT Tape to the flat metal flashing.

– Step 3: moulding by hand, and adhering the Effisus Bond FT Tape to the corrugated metal sheet.

– Step 4: pressuring the entire surface of the Effisus Bond FT Tape with a silicone roll in order to improve the adhesion strength.

– Step 5: applying the Effisus Bonding KF+P Adhesive to the entire perimeter of the Effisus Bond FT Tape applied.

Solution benefits:

– No need for specialised tools or labour

– No need for torch or hot-welding

– Quick and easy to install

– Adaptable to the non-predicted situations on site

– Immediate seal

– Long-lasting

– Permanently flexible – able to absorb structural and thermal movements

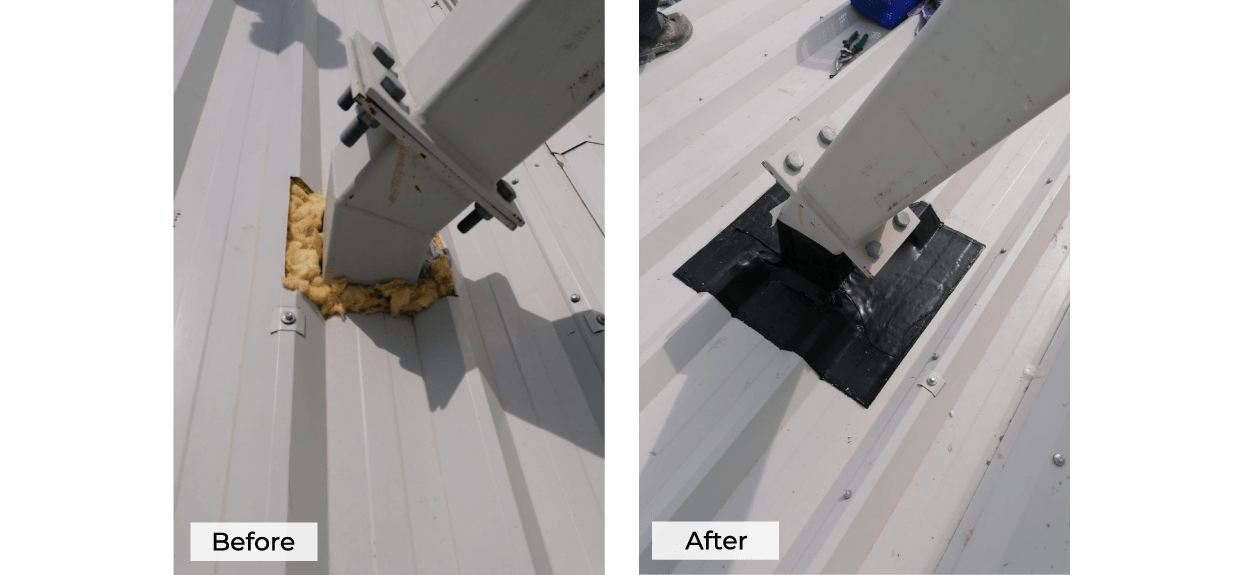

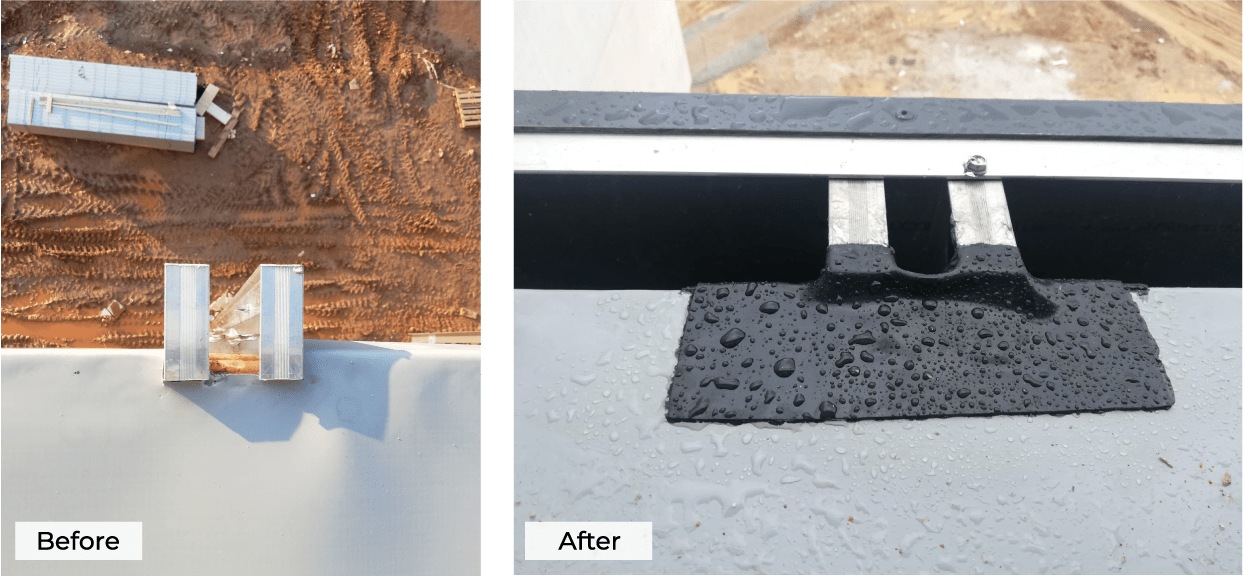

2- Perforations

Scope of work: sealing the perforation on a metal roof

Solution used: Effisus Bond FT

Installation description:

– Step 1: applying the Effisus Coat SP Primer and allow it to completely dry.

– Step 2: adhering the Effisus Bond FT Tape in sections to the perforation on each side, starting on the flat side.

– Step 3: adhering the Effisus Bond FT Tape to the base moulding by hand and fixing it to the corrugated part of the metal panel.

– Step 4: pressuring the entire surface of the Effisus Bond FT Tape with a silicone roll in order to improve the adhesion strength.

– Step 5: applying the Effisus Bonding KF+P Adhesive to the entire perimeter of the Effisus Bond FT Tape applied.

Solution benefits:

– No need for specialised tools or labour

– No need for torch or hot-welding

– Quick and easy to install

– Adaptable to the non-predicted situations on site

– Immediate seal

– Long-lasting

– Permanently flexible – able to absorb structural and thermal movements

3- Skylights

Scope of work: sealing the edges of a skylight

Solution used: Effisus Bond FT

Installation description:

– Step 1: applying the Effisus Coat SP Primer and allow it to completely dry.

– Step 2: adhering the Effisus Bond FT Tape in sections on each side, starting from the skylight edge.

– Step 3: moulding the Effisus Bond FT Tape by hand and adhering it to the corrugated part of the metal panel.

– Step 4: pressuring the entire surface of the Effisus Bond FT Tape with a silicone roll in order to improve the adhesion strength.

– Step 5: applying the Effisus Bonding KF+P Adhesive to the entire perimeter of the Effisus Bond FT Tape applied.

Solution benefits:

– No need for specialised tools or labour

– No need for torch or hot-welding

– Quick and easy to install

– Adaptable to the non-predicted situations on site

– Imme diate seal

– Long-lasting

– Permanently flexible – able to absorb structural and thermal movements

4- Perimeter finishes with parapets or walls

Scope of work: sealing a flashing detail in a wall

Solution used: Effisus Bond FT

Installation description:

– Step 1: applying the Effisus Coat SP Primer and allow it to completely dry.

– Step 2: adhering the Effisus Bond FT Tape to the flat part of the wall.

– Step 3: moulding the Effisus Bond FT Tape by hand and adhering it to the metal flashing ensuring that it is fixed to each profile surface.

– Step 4: pressuring the entire surface of the Effisus Bond FT Tape with a silicone roll in order to improve the adhesion strength.

– Step 5: applying the Effisus Bonding KF+P Adhesive to the entire perimeter of the Effisus Bond FT Tape applied.

Solution benefits:

– No need for specialised tools or labour

– No need for torch or hot-welding

– Quick and easy to install

– Adaptable to the non-predicted situations on site

– Immediate seal

– Long-lasting

– Permanently flexible – able to absorb structural and thermal movements

5- Perforations in facades

Scope of work: sealing flashing in joints with a facade.

Solution used: Effisus Bond FT

Installation description:

– Step 1: covering the hole in the joint with a small metal plate.

– Step 2: applying the Effisus Coat SP Primer and allow it to completely dry.

– Step 3: adhering the Effisus Bond FT Tape in sections to the metal plate.

– Step 4: moulding the Effisus Bond FT Tape by hand and adhering it to the perimeter of the circular tube.

– Step 5: pressuring the entire surface of the Effisus Bond FT Tape with a silicone roll in order to improve the adhesion strength.

– Step 6: applying the Effisus Bonding KF+P Adhesive to the entire perimeter of the Effisus Bond FT Tape applied.

Solution benefits:

– No need for specialised tools or labour

– No need for torch or hot-welding

– Quick and easy to install

– Adaptable to the non-predicted situations on site

– Immediate seal

– Long-lasting

– Permanently flexible – able to absorb structural and thermal movements

If you want to receive more information about Effisus services or products, please subscribe our Newsletter.

We are based in Cape Town and would appreciate more info.

Regards

Thanks for your comment, our commercial team will contact you as soon as possible.

do you have an Australian distributor for this product.

Has it been used / tested in the harsh Australian environment

Good afternoon Kevin,

Thank you for your interest in Effisus solutions.

Sara Ramos, from our commercial team, will contact you through email as soon as possible with all the information you have requested.