Why is it so important in your facade project?

A compatibility test confirms or measures how stable a substance is when in contact or adhered to another substance. It will ensures that the contact between two construction materials will not change the properties of each individually and if the performance of the two materials combined are suitable for the application designed.

During a facade construction project there are plenty of product combinations applied by different applicators at different project stages. Regarding to weatherproofing thematic, the most common problems are:

- Volatile organic compounds (VOCs) migration;

- Adhesion failure between 2 products surfaces;

- Chemically the products are not compatible when in contact;

- Discoloration;

A compatibility problem will interfere directly on the product life expectancy or even cause the failure of the vapour / water / air control sealing.

It’s imperative to perform compatibility tests whenever the behaviour of 2 or more products in contact or adhered is not known.

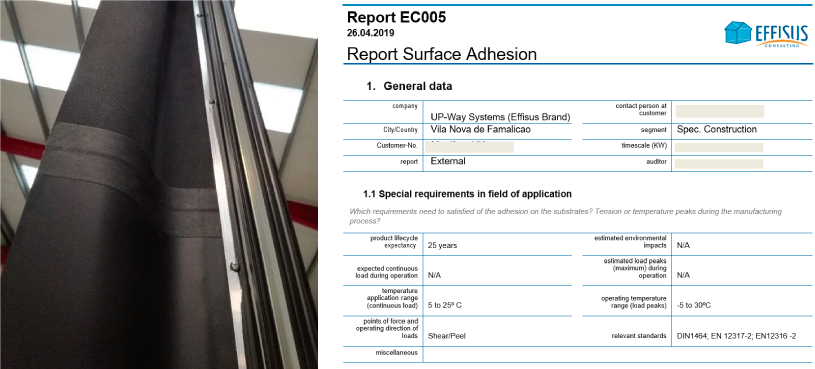

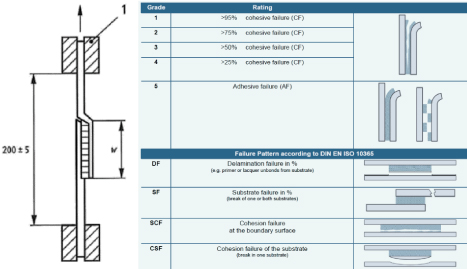

Depending on the products, expected load, weather conditions and the application is chosen the suitable test to confirm the compatibility.

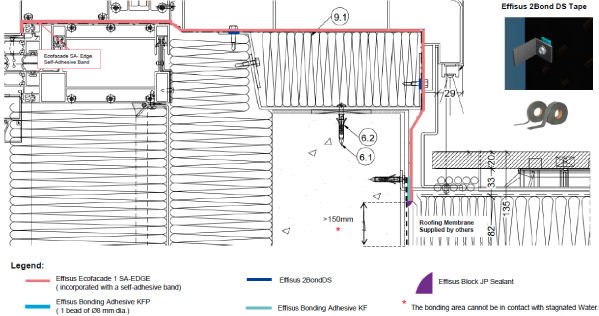

For instance when is tested the adhesion between a facade EPDM membrane and a Bituminous modified polymer roofing membrane at coping area, a shear and peel resistance test could be advisable.

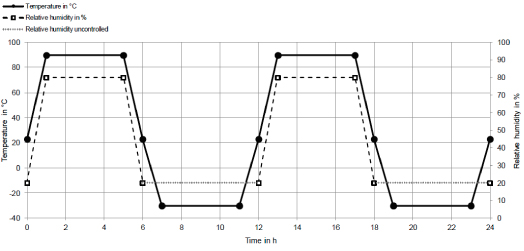

Sometimes the above tests are combined with climatic test. The purpose of the test is to conclude the behaviour on the bonding area against cycling/changing climate conditions in time lapse. This test shows a possible adhesion failure between the adhesive and the surface of the substrate in case of poor adhesion. The following graph shows 2 test cycles.

The conclusion is obvious, compatibility study between materials is crucial. In general the products are well specified individually but could fail as a full system on site.

All the parties involved in a project as architect, consultant and applicator should be responsible for specifying, supervising and testing this subject.

An incompatibility can result on a less efficient building, water leakage or condensations among other problems – always involving high cost corrections and occasionally without being possible to properly correct the situation.

Partner Testimony

Ringo Perez Gamote – Research Associate. CC Building Envelope

Lucerne University of Applied Sciences and Arts Engineering and Architecture.

“The compatibility test are crucial to avoid problems in the facade. During the manufacture of a facade element, or in the installation of this element on site, it is quite common that membranes and / or gaskets are in contact. Performing compatibility tests is very important to avoid unexpected reactions between the components that derive in permeability problems.

The use of components that come from the same supplier decrease the risk. Normally the supplier has already tested the compatibility between its products, being able to advise and indicate in advance the most optimal design solution. It reduces the development time as well as the number of compatibility tests to be performed.”

If you want to receive more information about Effisus services or products, please subscribe our Newsletter.

Lack of silicon sealant and EPDM membrane

Thank you for your comment! For any further questions please contact us: [email protected]