Metal Roofs – A Quick Analysis

Over the last two decades, metal construction has seen major growth. A closer look at the buildings around us, and we will see that most of our service, industrial and commercial buildings have a metal structure as well as a metal roof and/or façade.

In this article, we will focus on metal roofs and the advantages that have led to its market dominance. We will also point out some of its drawbacks and do a quick analysis of the most common problems associated with metal roofs. Finally, we will highlight one of its most common problems: leaks associated with metal roof joints, and point to some solutions to repair such issues.

A – Metal Roofs – General Benefits and Drawbacks

Benefits

- Durability

A metal roof is engineered to last decades, sealing out water and wind, and easily shedding snow. It is designed to resist hail, mold, mildew, rodents, and other animals. The roofing longevity will always depend on the type of the metal roof installed and on the quality of the installation, but metal roofs can last for more than 60 years.

- Lightweight

Metal roofs are very lightweight – much lighter than a typical flat roof solution with concrete slab. Because of their light weight, it’s possible to save on the roof’s supporting structure and reduce the number of supporting elements.

- Speed and ease of installation

Most metal roofing solutions come in large panels that are easily put together, meaning that the installer can install it quickly and easily. This represents considerable labour savings and ensures the job can be finished quicker.

- Fire resistance

Metal roof materials often are A-Class fire-rated, which means that they are non-combustible and have the best possible classification regarding fire resistance.

- Easy shedding of rain and snow

Metal roofs enable the quick shedding of rain and snow, making them a very efficient solution for locations with frequent snow.

- Eco-friendly

Metal roofs frequently have between 25 to 95% of recycled content, depending on the material, and are also almost 100% recyclable at the end of their life

- Quality finish

There are options on the market with very attractive, high-quality materials. Also, the variety of solutions available is quite large.

Drawbacks

- Cost

Metal roofs can be expensive. This will of course depend on the type of metal roof chosen – more expensive materials will usually last longer.

- Noise

Metal roofs can be noisy – especially during heavy rain or a hailstorm. This aspect can be minimized by using more insulation, or by adding sound barriers, but this will also increase the cost of the final solution.

- Denting

Especially on solutions with aluminum and copper, which are much softer than steel, a metal roof can dent easily. This can happen if, for example, large hailstones fall on it, or during the project conclusion when installing other equipment or during maintenance operations. If a roof is damaged, corrosion might develop quickly.

- Thermal movement

Metal expands and contracts significantly as it warms and cools, so it’s important that joints and fastening systems are designed to properly accommodate this movement. Otherwise, fasteners that secure the roof tend to come loose, and joints can open, causing leaks.

- Leaking

A metal roof must be installed correctly and as said before, joints and other details must be designed to accommodate any predicted movement, otherwise paths for leakage will be opened. Roofs with exposed fasteners are particularly vulnerable to future leakage problems. Another factor that might increase the risk of leakage is the non-conformity of the roof with the system’s minimum recommended pitch.

B – Metal Roofs – Typical Problems

Leaking

A metal roof can start to leak for several reasons, including environmental extreme events, installation error, or simply due to system deterioration. The most common situations that result on a leaking roof are:

- Failed fasteners – The screws are either too tight, too loose, or off-center, allowing water to enter at open spots.

- Failed seam – The seam where two panels are connected could be formed incorrectly or seamed improperly by the installer.

- Failed flashing – Flashing details at joints or additions on a roof, like pipes, chimneys, or valleys, are usually complex details that require precise installation. Flashing points can easily be the source of a leak.

- Failed sealants – Sealants or sealing tapes are used to seal out water, dirt, and other debris that could compromise a metal roof. If these are damaged, missing, or applied incorrectly, leaks could occur.

- Improper pitch – If the roof does not have the proper pitch and does not allow the easy shedding of rain, water may start to enter the roof at its weakest points: joints, penetrations, etc.

Corrosion

Most metal roofing has protective paints or coatings specifically engineered to resist corrosion. If this protective layer is simply blown away or dissolved, exposing the metal beneath, then corrosion will start.

Deterioration of the metal roofing coating may occur due to several factors:

- Building use – High winds, moisture content, and activities inside a building all contribute to extra tensile stress on a roof. For example, repetitive movement due to thermal expansion and contraction, or vibration causes microscopic cracking and scratching of the roof coating, and accelerates attack from water particles favoring corrosion development.

- Saltwater corrosion – Buildings close to the coast are more susceptible to corrosion development. This is because salt water, an electrolyte solution, contains more dissolved ions than fresh water, meaning electrons can move more easily. Since rusting is all about the movement of electrons, iron rusts more quickly in salt water than it does in fresh water.

- Dissimilar metals – When certain metals are put together, there can be a negative interaction that causes early corrosion that would not occur otherwise. So it is important to analyze such situations and, if necessary, install separation layers in order to avoid contact between such dissimilar materials.

- Cut edges – Cut edges on a steel roof will experience edge creep, which is minimal rusting occurring at the cut edge. Many details in a standing seam metal roof have folded edges that conceal the cut edge of the metal. The cut edges are vulnerable to weathering, oxidation, and pollutants because they are left exposed and do not have a protective coating, like the rest of the metal or aluminum cladding has.

Oil Canning

Oil canning (or stress wrinkling) is a natural phenomenon that appears as lines or waviness in the flat areas of a metal roof or wall panel. It is an aesthetic concern and typically has no impact on the performance of the panel – it is often only visible at certain angles and under certain lighting conditions.

Oil canning is caused by internal stresses within the panel. The most common causes for oil canning are:

- Overtightening fasteners

- Thermal movement not permitted

- Misalignment of the roof deck

- Stress introduced during production

Installation Error

Quality of the installation is critical. We can point some common installation errors that will later compromise the performance of the roof:

- Missing parts or accessories

- Improper flashing

- Loose screws

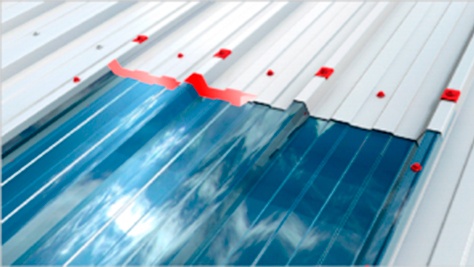

C – Leaks on Metal Roofs – The Devil Is in the Seams / Joints

Seams between roof panels, joints on flashing details, and joints between the flashing and the roof are usually the areas where the first leaks will appear. These are also the areas on a roof that will suffer from quicker degradation (excluding gutters), meaning that these are the areas that will require repairs earlier, in order to maintain the roof.

The most common issues seen on joints which will most probably cause leaks are:

- Corrosion – Joints are usually the areas where corrosion will develop most quickly. This happens because the coating was made fragile at the panel edges during production and cutting, or where the coating was perforated for fastening of the roof, etc.

- Open joints – Joints are prone to separation over time and this can create an opening that allows water to enter the building.

- Missing sealants – If a proper sealing solution was not used during the roof installation, then these joints are prone to developing leaks quickly.

D – Sealing Seams / Joints on Metal Roofs – Effisus solutions

1 – Effisus Easyrepair Tape

The self-adhesive Effisus Easyrepair Membrane is the ideal solution for sealing joints on virtually all types of metal roofs or facades. It creates a waterproof, moisture-proof, and airtight barrier, with no additional sealing required. The active sealing technology adhesive ensures superb adhesion to virtually any type of metal.

ACTIVE SEALANTS TECHNOLOGY

The Effisus Easyrepair Membrane uses an innovative technology with active sealants. This technology uses sealants that don’t have double connections between their carbon atoms, which results in an extremely stable molecular structure, which is resistant to light, ozone, and heat.

Through the use of a special primer, this adhesive “melts” into the surface to which it is applied. This creates an instant bonding to most known materials used in construction. It can be applied in environments with temperatures from -56ºC up to +93ºC.

Solution Benefits

- Resistant – Waterproof, UV resistant, and flexible up to -56ºC

- Universal – Compatible with different construction materials

- Durable – Over 20 years of service life expectancy

- Flexible – Complies with different installation requirements

- Easy to install – Easy to install and with no need for accessories

Effisus Easyrepair Variants

- Easyrepair White

- Easyrepair Grey

- Easyrepair Tan

- Easyrepair Black

- Easyrepair Copper

- Easyrepair Alumen

- Easyrepair Paint

- Easyrepair +

Supply Information

Effisus Easyrepair Membranes – Rolls of 15.2m length and a range of 50 to 1000mm width

2 – Effisus Bond FT Tape

Effisus Bond FT Tape is the ideal solution for permanently sealing flashing details on metal roofs of any type, saving time and labour – with a superior performance that will last as long as your roof. Its unique elongation capacity and flexibility guarantees that it can be formed to fit irregular shapes and surfaces, with no need for mechanical fastening, torch, or extra adhesives.

Effisus Bond FT Tape consists of an uncured EPDM membrane that has been laminated to an EPDM-based pressure-sensitive tape adhesive, integrating a proven peel & stick technology. After being cured, the tape is extremely resistant to moisture, UV, temperature changes, and structural movements.

Superior Formability Capacity

- Excellent formability to fit any shape or surface

- Proven peel & stick technology

- No torch or liquid adhesives

Exceptional Performance

- Resistant to UV and moisture

- Absorbs movement

- Durable

Typical Applications

- General purpose flashing

- Skylights

- Square ducts

- Large round ducts

- Parapet walls

- Facades

- Chimneys

Solution Benefits

- Universal – Forms itself to fit any irregular shape or surface

- Resistant – High elongation capacity, handles expansion and structural movements

- Durable – Resistant to high temperatures, UV, and moisture

- Flexible – Complies with different project requirements

- Easy to install – Easy-to-handle materials and common use accessories

3 – Effisus EverydaySeal Tape

Effisus EverydaySeal XTRA is a tear-resistant, UV-resistant, long-lasting, and water-resistant aluminum butyl rubber tape with very high tack and superior ageing resistance. It is used for masking applications and for sealing insulations, pipework, and ducts in HVAC applications.

The tape provides a reliable sealing of metals, wood, and plastics, as well as masonry and clean concrete surfaces.

Effisus EverydaySeal XTRA tape

- Adhesive tape with a butilic base, and a laminated PET/Alu/PET-composite, UV-resistant coating

- The adhesive is coated with a silicon-based film for easier application

- For sealing general flashing details in the construction industry and other uses

Typical Applications

- Sealing details on air conditioning, heating or ventilation, pipes or ducts

- Sealing connections between insulation panels

- General repairs on gutters, downspouts, and others

- General repairs on metal roofs or facades

- Industrial applications

Solution Benefits

- Robust – 100% waterproof, and UV-resistant

- Universal – Different widths for different needs

- Durable – High life expectancy and resists temperatures from -30ºC to +80ºC

- Flexible – Adapts to on-site demands

- Easy to apply – Simple-to-handle materials and no need for accessories

E – Case Studies

Case Study 1 – Sealing Joint on Metal Flashing

Solution used: Effisus Easyrepair Tape

Case Study 2 – Sealing Joint Between Roof and Skylight

Solution used: Effisus Bond FT Tape