Polycarbonate on roofs – Benefits and drawbacks

Polycarbonate has a series of advantages that makes it a very interesting choice for certain roofing applications, when compared with glass or acrylic. It is:

- a very strong and resilient thermoplastic material – virtually unbreakable with 250 times the impact strength of float glass and 30 times that of acrylic

- can withstand force

- extremely lightweight

- capable of withstanding extreme temperatures

- resistant to heat, sunlight, snow, and rain – lasts without fading or discoloring

- has an UV blockage feature

As said before, due to above mentioned qualities it is an effective roofing material for many applications, being used more and more on structures such as:

- decks

- garages

- patios

- sheds

- conservatories

- pool covers

- roofing on industrial warehouses

- awnings in commercial buildings

As the panels are extremely light in weight, they can be easily transported and installed wherever they are required.

Nevertheless polycarbonate panels have a few disadvantages when they’re compared to plastic or glass:

- they are not scratch resistant

- have a quite high coefficient of linear thermal expansion – its value equals 0,067 mm/m*ºC, which is one of the highest values of this parameter among currently used construction materials.

- its particular surface properties represent a major difficult for the bonding of adhesives or sealants

Joints on polycarbonate – The no.1 challenge when working with polycarbonate roofing structures

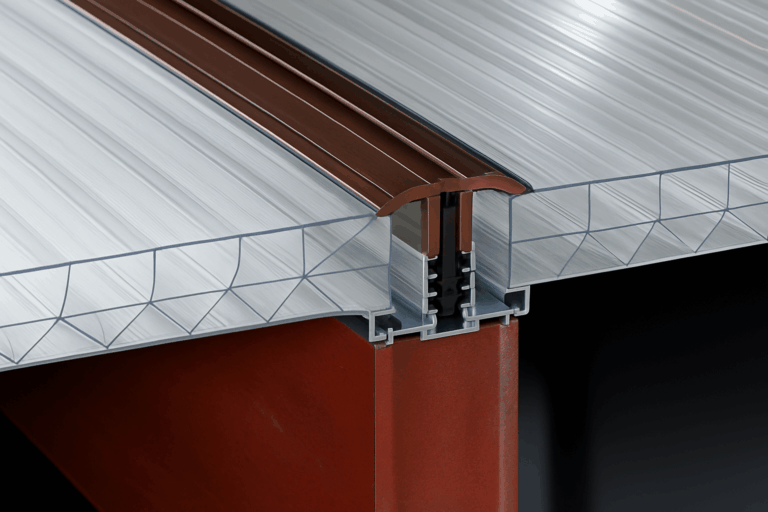

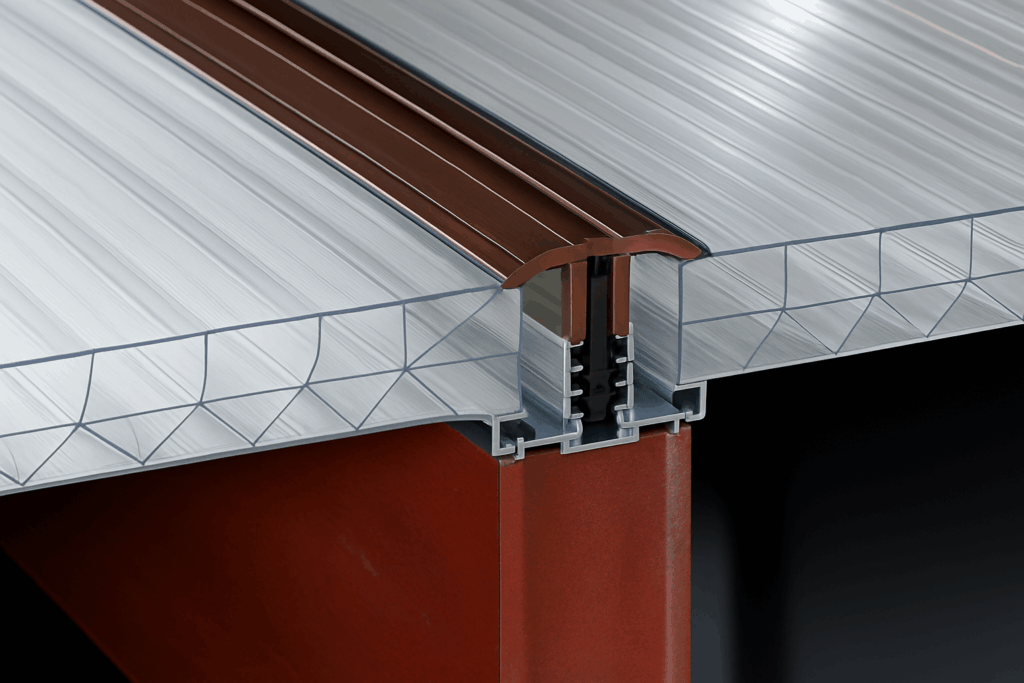

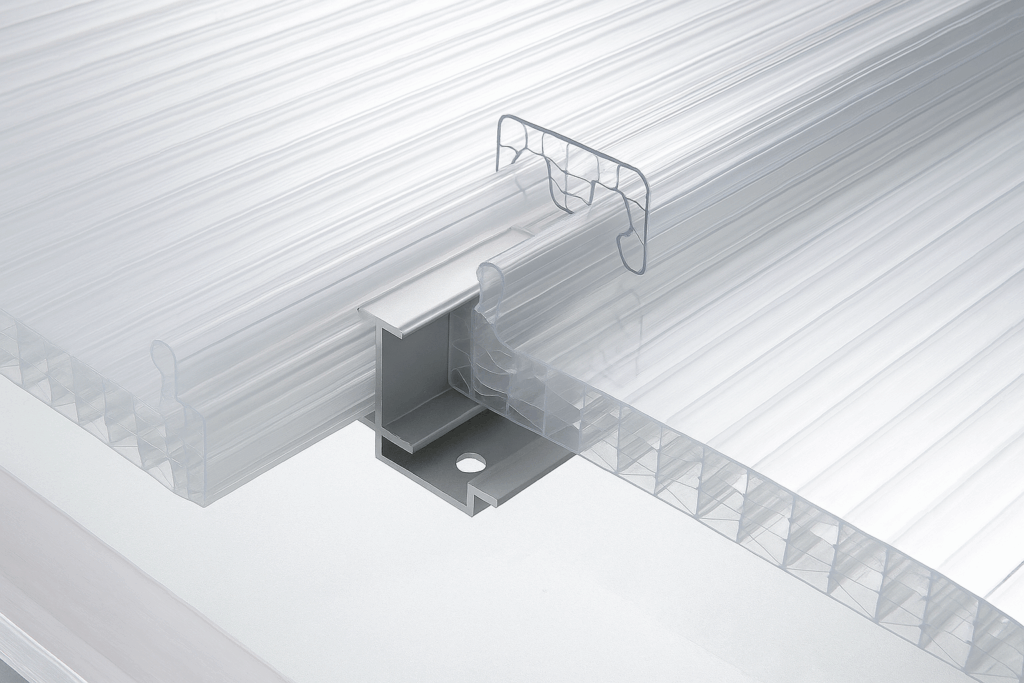

High linear thermal expansion of polycarbonate has to be taken into account during the process of installation – sheets should be loosely, rather than rigidly installed within the profiles, which enables the expansion of the material under temperature changes. The aluminum profiles system should be designed with regard to these conditions.

However, most of the times, the high expansion and movement of the panels puts so much pressure on joining materials, making it to failure and break. Many times the sheets start coming out or bulging. This is the no.1 pathology associated with polycarbonate roofing structures.

A failure of the joints of such systems represent a major failure of the system, as it represents water leakages, damages on roof components and its interior, contributing to the rapid degradation of the building. To the roofing contractor water leakages are the no.1 cause for additional costs after the installation is concluded.

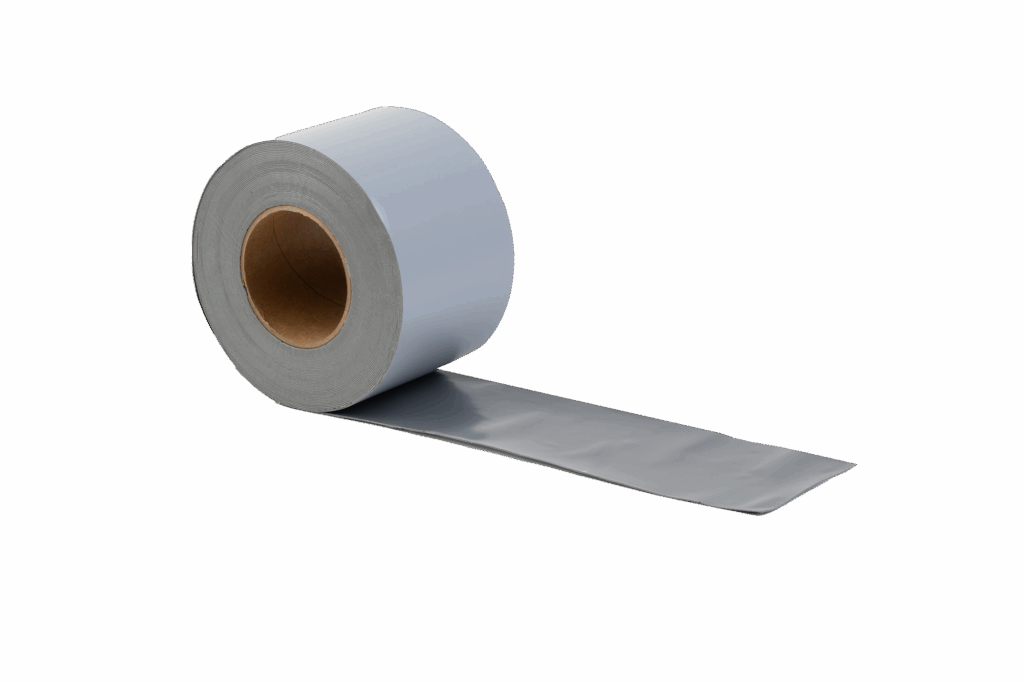

Most of the times, the solution will be sealing these joints with silicone or similar materials, or using standard bitumen or butyl sealing tapes. These solutions are not able to absorb the movement – silicones – and do not adhere properly to polycarbonate – tapes will get loose from the substrate very soon.

Sealing polycarbonate joints – Effisus Easyrepair: the solution

The Effisus Easyrepair Tape is the ideal solution to seal joints on polycarbonate sheets. It creates a waterproof, moisture, and airtight barrier, with no additional sealing required. It has an exceptional adhesiveness to polycarbonate and is installed in a fast and easy process.

It can be used to seal joints between polycarbonate sheets, or joints between polycarbonate sheets and other construction materials, such as metal, concrete, plastics, etc.

Effisus Easyrepair – Main advantages:

- Exceptional adhesiveness on polycarbonate and other construction materials

- Permanent sealing of any joint or leakage point

- Easy and fast installation, with no need for accessories

Effisus Easyrepair on polycarbonate joints – Typical applications

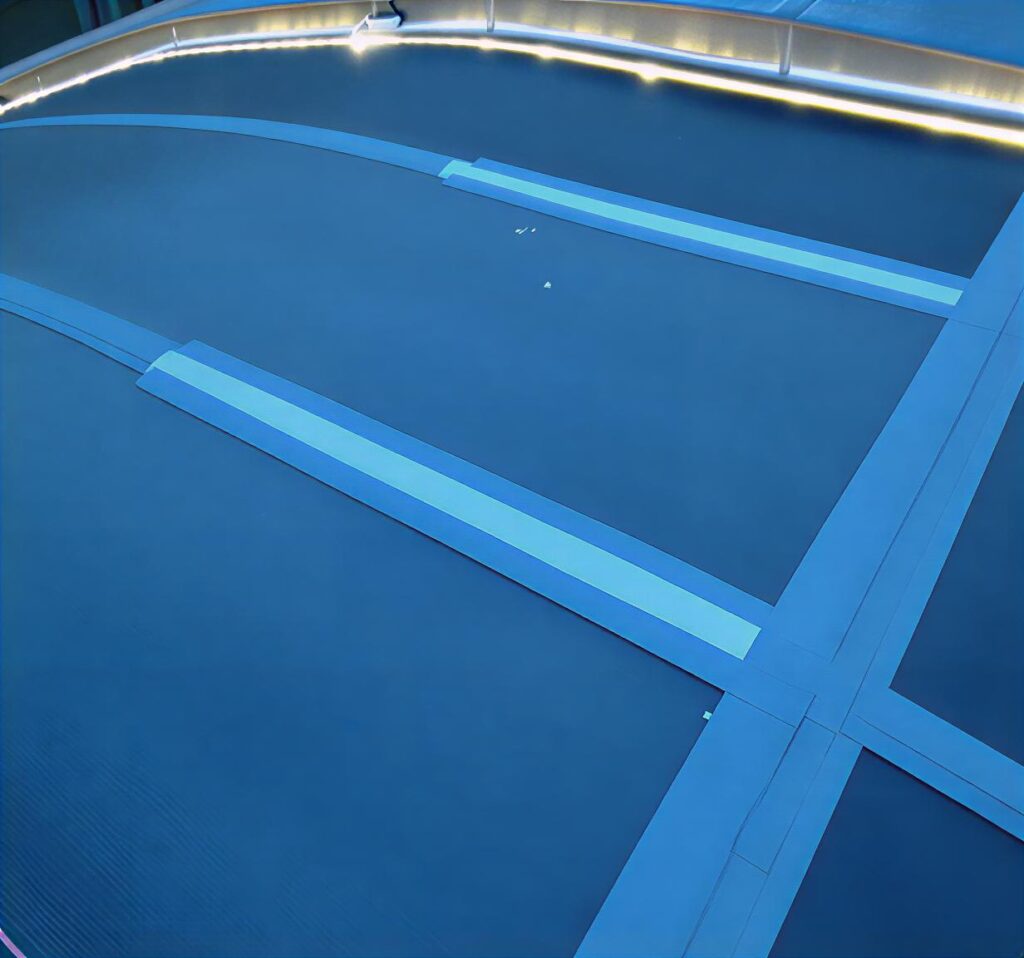

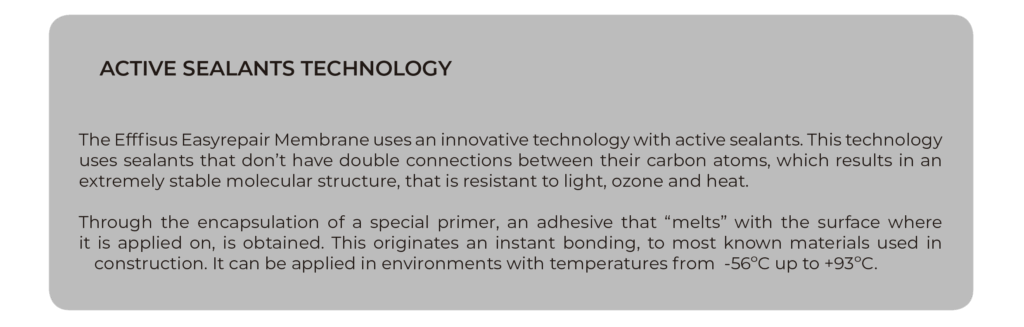

Sealing joints on polycarbonate curve skylights

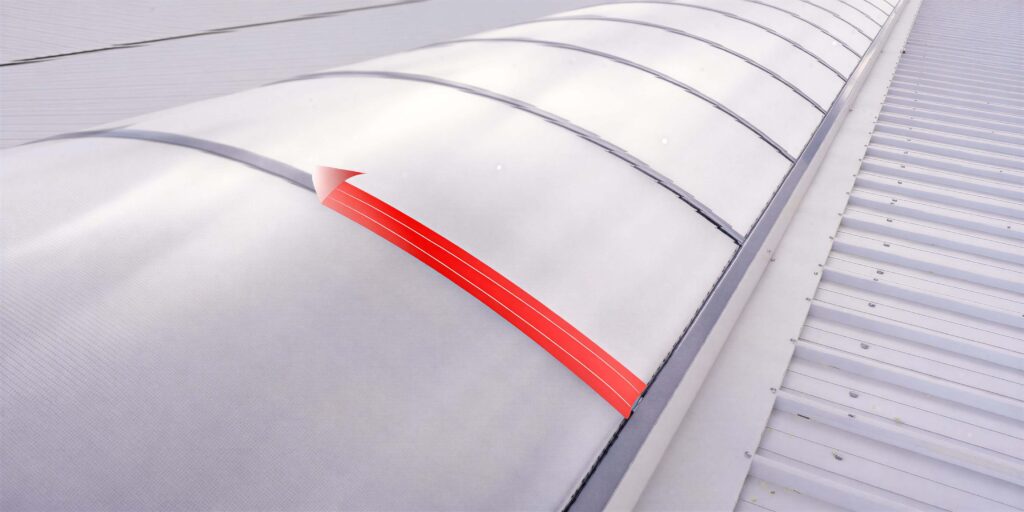

Sealing joints between metal flashing and polycarbonate skylights

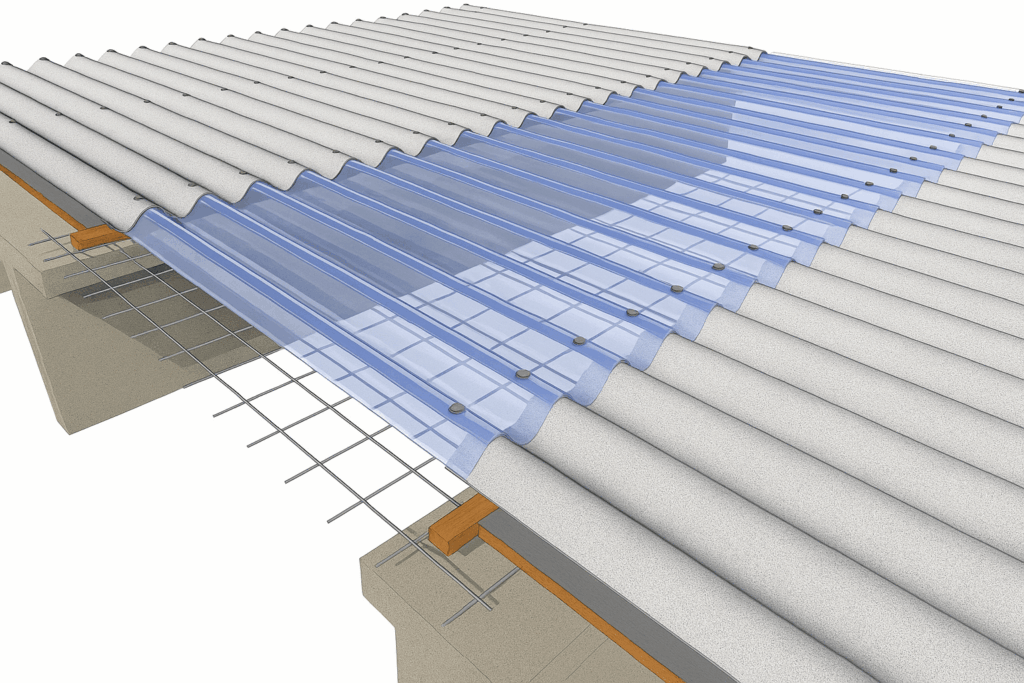

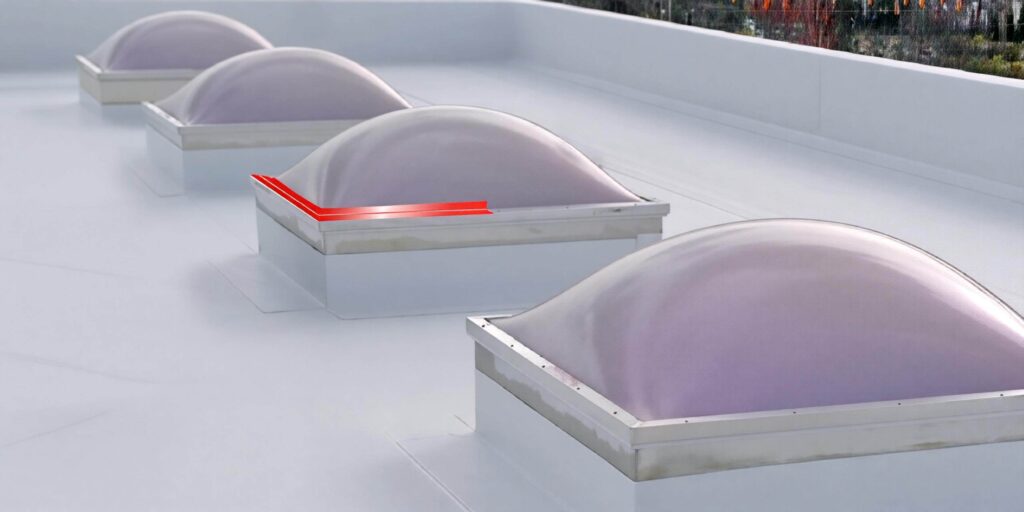

Sealing joints between polycarbonate sheets and corrugated metal roofs

Sealing joints between polycarbonate sheets

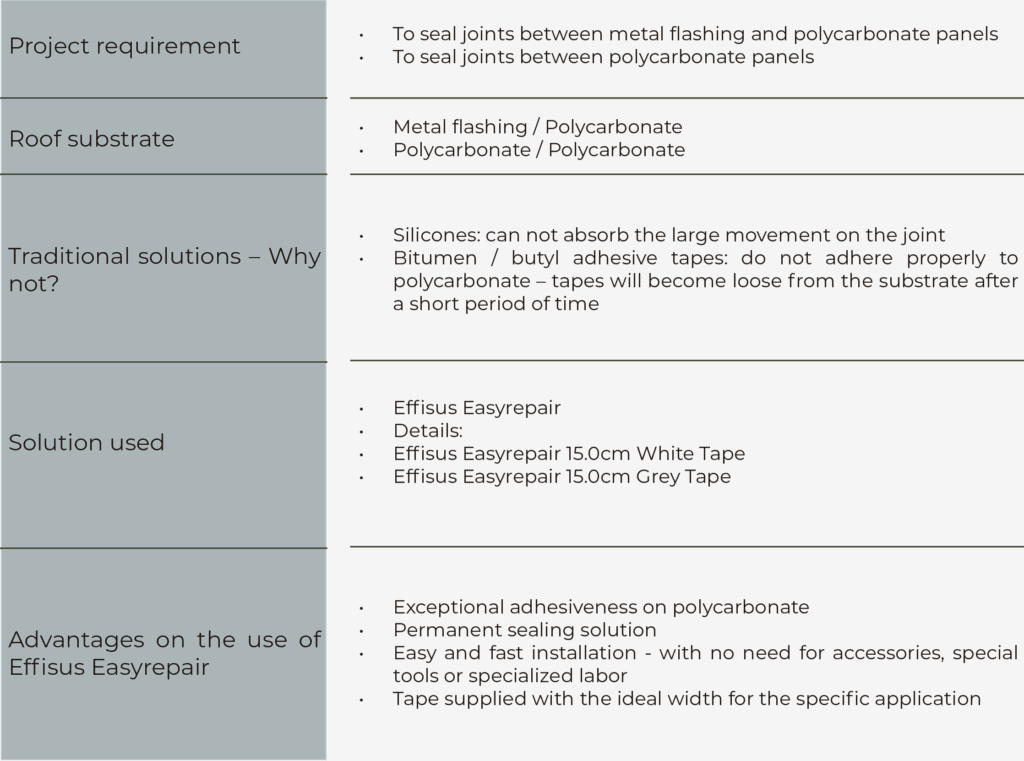

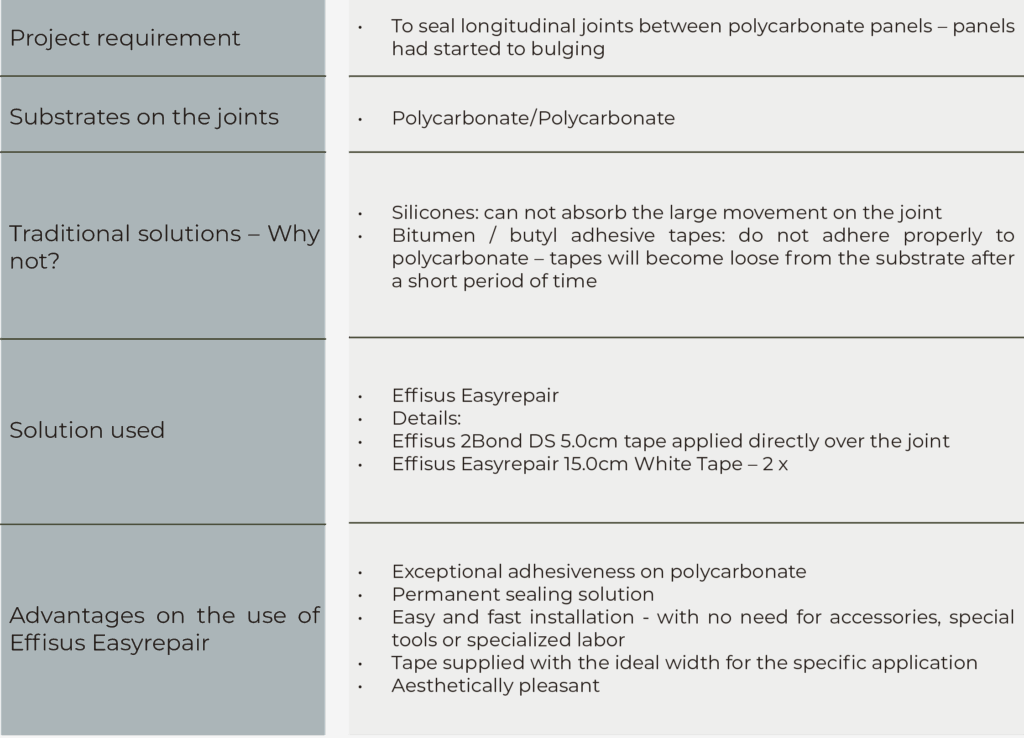

EFFISUS EASYREPAIR: SEALING POLYCARBONATE JOINTS – CASE STUDY 1

EFFISUS EASYREPAIR: SEALING POLYCARBONATE JOINTS – CASE STUDY 3